Govt.of India Recognized Export House

Our Factories are well equipped with the latest state of the art imported Machineries. A modern state-of-the-art machineries are available in-house to make sure that quality is always delivered at every stage of production. The key to run any smooth manufacturing operations lies in the effective establishment & governance of infrastructure The infrastructures at Fashion Gate has marked by a perfect harmony among the various functional units namely Knitting, Compacting & Sewing Machines. All the units at Fashion Gate are well equipped with the latest machinery to keep in pace with the changing & challenging needs of the customers around the world.

Cutting Room is handled both manually (for stripes, Jacquards to get the stripes and design set in side seam) and also mechanically, i.e., Lay cutting of cloth by a cutting master to make consistent and sharp cuts.

After precision cuts are made in our Cutting Section, the journey continues to our Sewing Section — the powerhouse of garment creation. This is where expertly cut fabric pieces are transformed into beautifully crafted garments with seamless stitching and impeccable finishing.

The finished garment is then subject to a thorough check by skilled supervisors, even the smallest defect is not overlooked.

Ironing is the Final phase of production of the garment, which has been doing with latest machines. The garments are steam pressed and vacuum sucked in order to take away any excess moisture in the garment due to steaming. After pressing the garment goes for final packing.

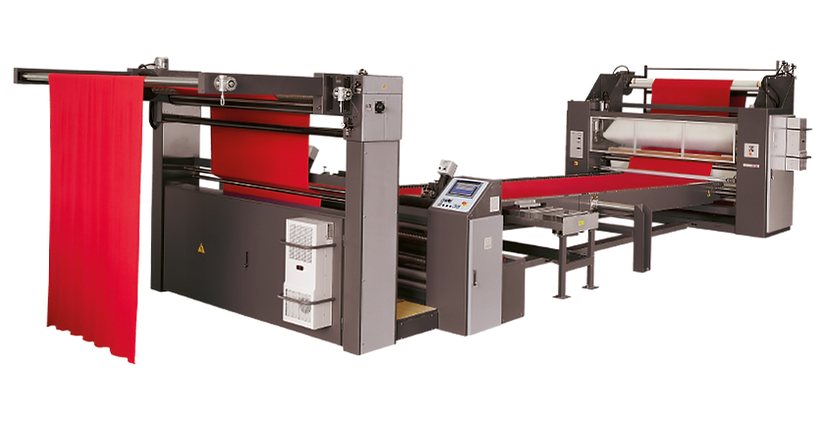

Our Factories are well equipped with the latest state of the art following imported Compacting (Shrinkage Control) Tube Tex - USA, Ferrorrow - Italy, Lafer - Italy & Raising Machineries. A modern state-of-the-art machineries are available in-house to make sure that quality is always delivered at every stage of production

Compacting Machine

(Shrinkage Control)

We are very particular in keeping the shrinkage levels well below permissible limits. Every garment that goes out of our factories are compacted as a rule.

| S. No | Compacting Type | Machine Maker | Imported from | No of M/c. | Capacity per day |

|---|---|---|---|---|---|

| 1 | Tubular Compacting |

|

USA | 2 Mc | 16 Tons |

| 2 | Tubular Compacting |

|

Italy | 3 Mc | 18 Tons |

| 3 | Open Width Compacting |  |

USA | 3 Mc | 30 Tons |

| 4 | Open Width Compacting |  |

Italy | 1 Mc | 10 Tons |

| 5 | Sintec |  |

Italy | 1 Mc | 10 Tons |

| 6 | Raising Machine |  |

Italy | 2 Mc | 6 Tons |

| 7 | Peach Finishing Machine |  |

Taiwan | 1 Mc | 6 Tons |

| 8 | High Speed Double Drum Raising Machine |  |

Italy | 1 Mc | 6 Tons |